Adrian Tippins lifts the lid on what you – and your juniors – need to know about basic arrow literacy.

I’ve always thought that the hardest thing for novice archers is attempting to understand and navigate the technical minefield that is unfortunately an essential part of archery.

It’s really easy to feel overwhelmed and incompetent. Whilst you can still shoot good scores without having technical knowledge, there are situations where an understanding is essential – especially when it comes to making a purchase.

Most archers at some point or another have bought an incompatible item or something that’s the wrong size or weight. Purchase mistakes are especially prevalent when it comes to arrows, as there are multiple weights and dimensions to get right.

It’s normally pretty straightforward if you’re using parts native to the brand and model of the arrow shaft, but there are lots of occasions where you may well be using a third party component, such as one of the excellent products from TopHat or Bohning for example.

The method of sizing & labelling varies greatly within brands – with a little knowledge, research and the application of some very basic maths you can make sure all of your new parts fit.

The aim of this article is to arm you with basic arrow knowledge. There’s more to learn – there always is – but. By the end you’ll hopefully understand exactly what you have and what parts fit it. There’s material here for beginners, novices, and experienced archers alike, and this knowledge should inspire a lot more confidence when it comes to making a purchase.

Arrow literacy: Weights and measures

The first thing to understand about arrows is how they are measured. The correct form of measurement is the AMO measurement. The length is taken from the nock groove to the end of the shaft EXCLUDING any points or inserts. If you’re buying arrows online or in store you’ll need to communicate the required AMO measurement.

Over the years I’ve seen way too many people buy arrows too long for them because they have given an end to tip length rather than the AMO. The purpose of the AMO method is to put everyone on the same page and gain an industry standard method for consistency of product.

All modern shafts will have numerical information printed on them. Deciphering this information is the vital first step. You may have noticed that aluminium arrows have a four digit number printed on them. An example of this may be something like 1616 or 1916.

This number is often incorrectly referred to as the “spine” of the arrow. It is in fact the tube measurements. There are two measurements contained in this number. The first two digits are the external diameter in 64ths of an inch. The last two digits are the thickness of the tubing wall noted in 1000ths of an inch.

We’ll now look at how this number and some basic maths combine in order to make a purchase. Let’s say you needed to buy some glue over nocks for a a 1616 taper swage arrow such as an Easton Jazz or Tribute. We know the size of outside diameter is listed in 64ths and that 16 is one quarter of 64. Therefore the correct size nock for this arrow is the ¼.

If the first two digits of the number are 18 the correct size nock would be the 9/32. This number scaled up would give you the 18 64s. If the number is 20 the nock would be 5/16. This principle will ensure glue over nocks, inserts and screw in points will be as flush to the shaft as possible.

Aluminium arrows that are over a 12 and under a 20 tend to be fitted with a Uni-Bush at the rear. This is a little adapter that narrows the aperture to accept standard nock fittings. Uni-Bushes slim the aperture down to 12/64ths.

Aluminium arrows of 20 and over will normally have a ‘Super Uni-Bush’ taking the aperture down but to a much fatter 19/64ths. These numbers of 12 & 19 are magic numbers in arrow building. Companies like Beiter will actually size their nocks with these prefixes. Easton size the 12 as ‘G-Nocks’ and the 19 a ‘Super Nock’.

It’s a really good idea to know the internal and external diameters of any arrows you might be using. This information can normally be gleaned from the manufacturer’s website. The dimensions are normally listed to three decimal places. A common example of an internal diameter of thin full carbon or hybrid arrows is 0.166”.

Ballistic items including arrow building components are weighed using the grain system of measurement. This system has been around since the Bronze Age.

The weight of one grain is nominally based on the weight of a cereal grain believed to be that of a grain of barley. Points etc. are weighed as a total mass such as 120 grains. Shafts are listed in GPI – grains per inch. They are listed this way as people will cut them to different lengths, thus altering the overall weight.

Simple multiplication of the length x GPI will give the total shaft weight without the need for physical weighing on scales. One grain has the modern day equivalent of 64.798 milligrams.

Arrow literacy: Front of centre explained

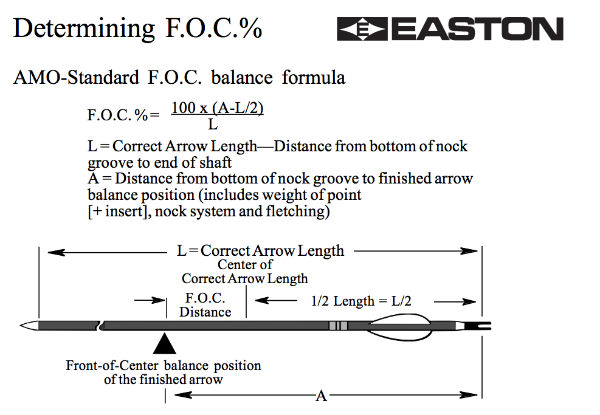

In simple terms, front of centre is the arrows balance point once the arrow is totally configured. Sometimes FOC is shown as a percentage figure which refers to the percentage of the arrow’s total mass which is located in front of the central point.

This is probably the most overlooked element of arrow configuration and shot tuning. It does however have a major influence on arrow flight characteristics and trajectory.

FOC is a very important consideration when shooting longer distances but less so for shorter indoor rounds. An arrow has a nose, a tail and flight stabilisation surfaces, usually vanes (fletchings) or spinwings. In avionics, a flight configuration would be referred to as the trim setting.

If the mass and balance of a projectile is placed too far to the rear it would turn around in mid flight. A darts player can hold a dart point backward and throw it a the board. The weighted rear would catch up and overtake the front and land point first into the board.

If an arrow’s balance is too far back it will have a wobbly flight that will be hard to tune out. If the weight is too far forward the projectile will have poor trajectory and will want to nose dive.

Stability requires weight, but good long range trajectory requires the container or packaging to be aerodynamic and lightweight. Therefore it’s really important to strike a healthy balance between the two.

Everything that gets added to to the shaft affects the FOC. Points have the biggest influence on FOC as they are a heavy item compared to other arrow products. (Later on we will be taking a more in depth look at points and how we can use them to manipulate FOC.)

Here’s a more scientific explanation of FOC for those of you that are mathematically minded. FOC is a measurement of where the centre of mass is relative to the actual centre of the arrow. Because of this, adding weight can be an advantage.

For example, installing a pin nock adapter in the rear can neutralise the affect of selecting a point with an extra 10 grains at the front. The FOC and trajectory will stay pretty much the same even thought the overall mass of the arrow has increased. Altering FOC can either improve or worsen sight marks depending on the position.

Most of my recurve customers prefer the weight further back to maximise sight marks. My compound customers tend to favour nose-heavy arrows for stability as sight marks are less of an issue with compound shooting.

Arrow literacy: Spine

Another number to be found on most shafts in the spine rating. In simple terms the spine of an arrow or “Static Spine Deflection” is the amount of flexibility an arrow shaft has or how stiff it is.

A shaft’s length in combination with shape, material, diameter and wall thickness will dictate the spine rating. An arrows spine rating can range from 285 to 1800. The lower number the stiffer it is.

Static spine is measured by supporting a shaft 28 inches apart and applying 1.94lbs of pressure to the middle. The amount of bend or “deflection” is then measured in 1/1000 of an inch. If the bend is half an inch it would be labelled as 500.

There is another element to spine that isn’t listed on the arrow. This is dynamic spine. Dynamic spine still refers to how much the arrow bends but whilst it’s in flight under the kinetic load of the bow. As all bows and arrows have different configurations dynamic spine is hard to measure and quantify.

When selecting a shaft using a manufacturer’s chart the figures listed will always be the static spine rating. Dynamic spine is much more of a tuning consideration where things like point weights and vane drag factors will affect the dynamic spine.

The spine stiffness will increase with with the bow poundage and archer’s draw length. Selecting the correct spine is not only important for good flight characteristics but also for safety.

Arrow literacy: What’s in a name

On arrows such as the ACG, ACE and X10 the core sizes are listed on the arrow. For example the ACE will sport “1206”. This gives us the same information as the numbers on the aluminium arrows in the exactly same way.

We can now deduce that the wall thickness of the core is extremely fine and the internal diameter has the magic number of 12. This means that standard G-Nocks will fit directly into the shaft without the need for any bushes. You can now start to see the importance of diameter numbers. An X10 arrow only has three numbers as the core is only 9/64ths wide.

The nomenclature of the Easton ACC is probably the most confusing. Apart from the spine rating it has an added designation that others don’t and also feature unique core sizes.

A popular example of this is “3-04”. The first number denotes how many carbon wraps have been used and last two numbers are the last decimal places of the core diameter. If the first number is followed by an “L” or an “X” it denotes that it’s a light or extra light variant of that model.

When the industry talks about or lists these arrows they tend to use the designation rather than the spine just like the aluminiums. ACC arrows other than -00 size cores will have a Uni-Bush to accept a standard nock. -00 sized cores are 12/64ths so the nocks fit in directly. This also means that you can use ACE hardware and any other 0.166” products if you wish.

Arrow literacy: Series & Weight Coding

Most top end Easton arrows carry a weight coding. This appears as a “C” number on the shaft such as C1, C2, C3 etc. After the shafts have been made they are carefully weighed and sorted into batches to ensure that you get a dozen shafts that are as close in weight as possible.

Weights vary due to fact that raw materials that they are made out of can differ. Again the ACC gives this information in a different way. Historically the ACC has displayed “Series DM” for example. (I’m led to believe that this refers to the different batches of carbon.) The alphabetically lower letters denote lighter weights, so DM is lighter than DN, DP is heavier than DN.

The series letter on ACG, ACE & X10 has a different meaning. The letter signifies a design revision/later version. Normally these revisions are cosmetic with a change to the livery or the addition of information to the shaft.

The higher the letter in the alphabet the more current the version is. In recent years many manufacturers have added a tiny laser etched serial/batch number to shafts. This can help to trace the origin of the product in the event of a failure or recall.

If you’re looking to replace a set of arrows on a like for like basis it’s important that the new set has the same weight coding if you want to have the same sight marks and performance.

Nocks

There is a massive choice of styles and models in the market place when it comes to nocks. Before making a purchase make sure you do your homework to ensure that you acquire the correct nocks for either compound or recurve shooting as the variants will differ in shape and size. As we are focussing on the essentials, to keep things simple here I’m only going to split nocks into three groups.

Insert Nocks

This variety is the most common and basic nock. It has a post that secures via press fit directly into the arrow shaft or a rear bushing. These normally come in two post sizes: 12/64 & 19/64.

Pin Nocks

Pins are by far the most popular system for intermediate to high end arrows. A small metal post is inserted into the rear of the arrow which allows a nock to be placed on top of it. The nock itself has a hollow which forms a cap to go over the adapter post. This makes changing nocks really quick and easy and the post shields the rear end from impacts.

Glue On Nocks

Some low end arrows end arrows have a solid rear end with is turned into a cone. The nock is then physically glued over the cone. A broken nock of this type requires more work to change as the arrow has to be stripped and cleaned before gluing on a new one.

Nocks come in only two groove sizes, small and large. It’s important to get the right size. Recurve strings normally utilise the smaller size whilst compound strings require a large groove. However, be aware that the strand count and the gauge of serving filament could well mean that a large groove is better option for a recurve string. Ask your dealer.

Loose nocks could fall off the string and cause dry firing which is potentially harmful to the bow and archer. Tight-fitting nocks will cause the arrow to have really poor performance as it will take some of the bow’s energy just to get disconnection from the string.

Great store of information. That said no information on the In/out nocks used by many Olympic Archers.

Good point. I will see if I can dig up something as to why.