As straight as an arrow: Everyone takes the importance of arrow straightness as a given – but is it possible to quantify? James Park and a group of fellow archers undertook a test to find out…

As you would expect, the arrows did not group as well, although those with the angled fletches did not suffer nearly as much

A group of enthusiastic archers recently got together to consider the importance of arrow straightness. ‘Got together’ is a way of saying that eleven of us collaborated on a project, communicating using the internet. The group consisted of Rick from Canada, Rick from the USA, Konstantinos from Greece, Pat, Adam, Vincent, Trent, Andrew, Danie, Scott and me from Australia (where we covered five States of Australia). That is a truly multi-nation project. The project started with (the Canadian) Rick wondering if I had ever studied how straight arrows needed to be. I said that I had not but that it would be an interesting thing to try. I coordinated the project from Melbourne, where our testing was also done.

James has done plenty of arrow testing before, but never anything that specifically measured the impact of a decrease in arrow straightness

We decided to test aluminium arrows as used for World Archery indoor events. Aluminium shafts were selected because they are available with very good straightness specifications, and because we could change their straightness in a controlled way.

Hence, most of our testing was conducted using Easton Technical Products 2315 X7 shafts. We also tested 2213, 2512 and 2712 X7 aluminium shafts, and Protour 380, LightSpeed and LightSpeed 3D shafts as a comparison.

We purchased a number of 2315 X7 shafts, together with (mostly) Easton Technical Products components. First we tested their straightness as we received them – they were very good, but we made a couple of small corrections to get them even better. That is, they were well within specifications of 0.001 of an inch. We fletched some with the fletches at an angle and some with the fletches straight along the shaft. All testing was done using a shooting machine and Hoyt Pro Comp Elite compound bow at a distance of 25 metres.

These arrows were tested through a shooting machine with straight fletchings…

Initial group testing was disappointing – the groups were larger than we wanted. We were after groups significantly smaller than would be required to obtain a perfect score.

After some careful thought the nocks were changed and the group size immediately reduced. Of the nocks we tested, we obtained the best groups using Easton MicroLite Super Nocks. We speculate that they gave us the best group results because the distance between the end of the shaft and the nock groove is very short.

The arrows fletched with the fletches at an angle to the shaft’s longitudinal axis grouped significantly better than those with no angle.

We then bent some of the arrow shafts, first to 0.003 of an inch and then to 0.006 of an inch, and retested the grouping. As you would expect, the arrows did not group as well, although those with the angled fletches did not suffer nearly as much as those with the straight fletches. We increased the fletch angle for some shafts and the group size nicely decreased.

…while the same arrows showed a tighter group with angled fletchings

LightSpeed 3D and LightSpeed arrow shafts are constructed from carbon fibre composite material and their straightness is set. The 3D shafts are nominally straighter than the others, and that straightness difference was also apparent in our testing.

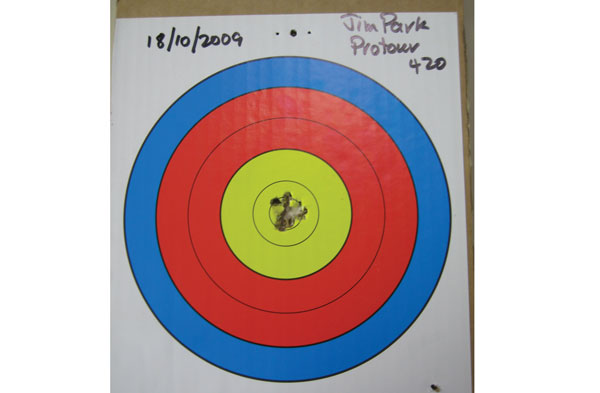

Some arrows were found to be very accurate indeed. One set of 2512 X7s with very short nock adapters was found to group all in the same hole at 25 metres: after many shots the hole in the target was just 3mm greater than the arrow shaft diameter. That 3mm was probably our aiming error.

Altogether, we shot a few thousand shots during the testing – typically about 50 for each test, spread over about two months in early 2017.

Overall, our findings were:

That it is worth paying the additional premium to purchase the straightest arrows.

Additionally, we found nock selection is very important in the grouping ability of a set of arrows: our expectation is that the nocks with the shortest distance between the end of the shaft and the nock groove will be the best.

You should definitely have the fletches set at an angle to the longitudinal axis of the shaft: about one degree is sufficient.

Another point to consider is that, prior to an important tournament it would be wise to change all the nocks on your arrows for a new set.

All in all, we discovered high quality arrows that are set up well can provide very good accuracy indeed.

Straight arrows are, of course, important, but just how important is what James and the group set out to discover

Several of our team members had previously published papers in professional journals, the others had not. I undertook to try to manage the project in such a way that we could try to publish the work so that the team members who hadn’t published before could see what is involved. We have succeeded, and you should be able to find our paper in the Proceedings of the Institution of Mechanical Engineers, Part P: The Journal of Sports Engineering and Technology (http://journals.sagepub.com/). (A search in Google Scholar using ‘JL Park archery’ should find it).

Would we do it again? I think so.